Heat Sources

Exhaust gas

Many production processes generate waste heat in the form of exhaust gas. Often, this heat is simply released into the atmosphere and goes unused. The heat, however, contains a large energy potential which can be used for generating cold via adsorption technology: Both for cooling manufacturing processes, and for air conditioning the production facilities in order to create a more pleasant and productive room climate for the workforce.

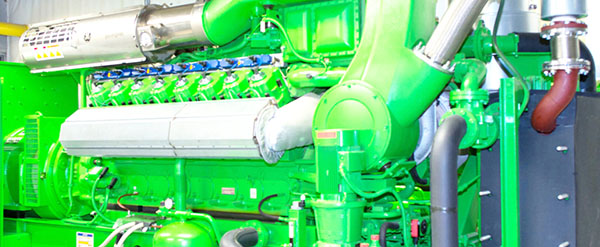

CHP Plants

Heat, Power, and Cold: Making Optimal Use of Energy Combined heat and power plants (CHP) work according to the principle of combined heat and power. As a result, they use the energy used much more efficiently than would be possible with the conventional, separate supply of electricity and heat. However, many CHP operators are wondering what they should do in the summer with the heat generated. The ideal answer here is the additional integration of an adsorption refrigeration system.

Fuel cells

Like gas-powered cogeneration plants, fuel cells generate electricity and heat, and with their relatively high cooling water temperature, they are particularly suitable for combined heat and power plants (CHP) and therefore also perfect for combining with adsorption chillers. This interaction is very beneficial in more ways than one: The generated electricity reduces electricity bills, and the cooling capacity is provided at the same time with almost no additional electricity needed.

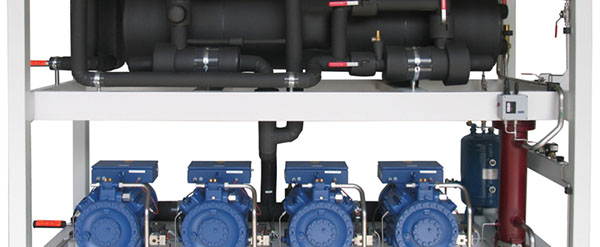

CO₂-Chillers

In order to be able to continue to operate their refrigeration systems without F-gases, which are increasingly being taken off the market, more and more supermarkets and other cooling system operators are turning to CO₂ systems. The waste heat from transcritical CO₂ chillers has exactly the right temperature level to drive adsorption cooling.

Compressed air

Almost all manufacturing companies use compressed air. At the same time, the need for cooling, both for production and for buildings, is constantly increasing, driving energy demand. Adsorption cooling offers an ideal approach for generating cold and reducing energy costs through heat recovery.

District Heat

local heat is usually generated together with electricity (combined heat and power). The efficiency of this process is much higher than with conventional power plants. This makes district heating an efficient and resource-saving option for energy supply. Their use becomes even smarter when district heating is used to drive an adsorption refrigeration system.

Process Waste Heat

Industry and trade need artificially generated refrigeration – and this demand is growing steadily. At the same time, electricity prices continue to rise. The increasingly stringent climate protection goals – and the associated regulations – also call for plant technology to be made energy-efficient and environmentally friendly. Many companies face challenges that can hardly be overcome with conventional solutions.