Economically and energetically smart

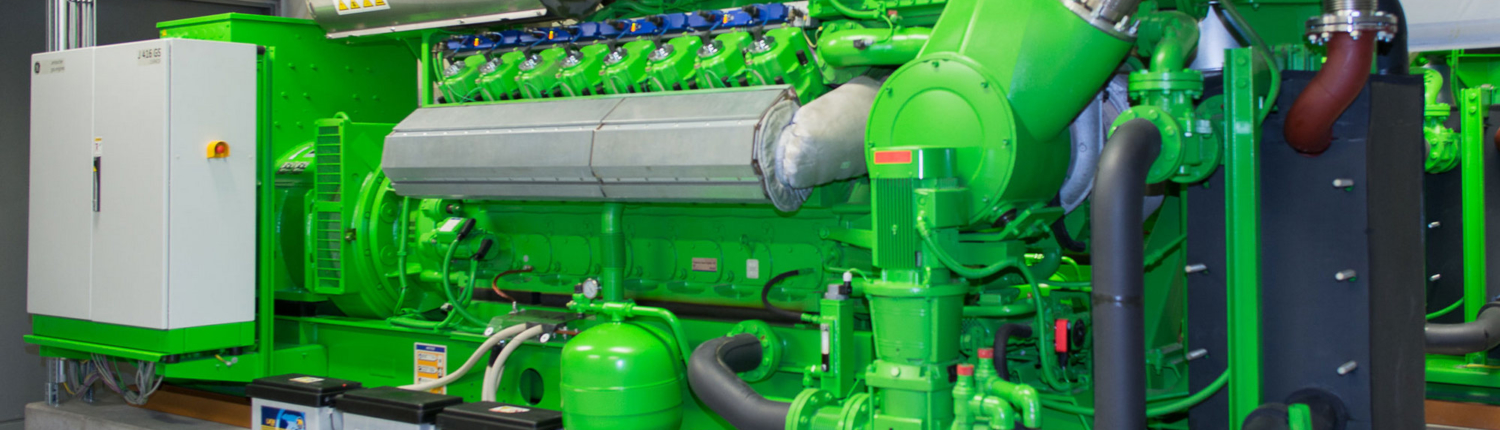

Combined heat and power plants (CHP) work according to the principle of combined heat and power. As a result, they use the energy used much more efficiently than would be possible with the conventional, separate supply of electricity and heat. However, many CHP operators are wondering what they should do in the summer with the heat generated. The ideal answer here is the additional integration of an adsorption refrigeration system. Because the conversion of excess heat into cold – e.g. for air conditioning – ensures optimal utilization of the system throughout the year – and can thus improve its profitability. Decisive is an intelligent control system. It helps to optimize the overall system by flexibly coordinating the generation of heat, electricity and cooling.

Combined heat and power not only reduces electricity costs significantly, it also relieves the power plants and supports the decentralized energy supply approach.

The connection to the power grid offers additional advantages: peak loads can be covered by mains power, an overproduction of electricity can be fed into the grid – and network redundancy ensures the supply is always secure.