Heat Sources

Exhaust gas

Many production processes generate waste heat in the form of exhaust gas. Often, this heat is simply released into the atmosphere and goes unused. The heat, however, contains a large energy potential which can be used for generating cold via adsorption technology: Both for cooling manufacturing processes, and for air conditioning the production facilities in order to create a more pleasant and productive room climate for the workforce.

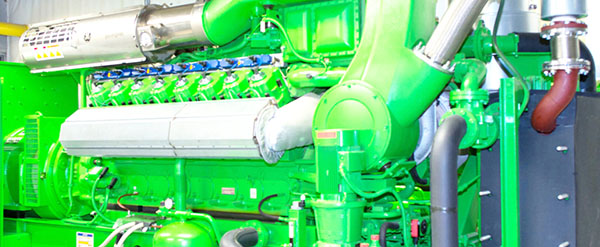

CHP Plants

Heat, Power, and Cold: Making Optimal Use of Energy Combined heat and power plants (CHP) work according to the principle of combined heat and power. As a result, they use the energy used much more efficiently than would be possible with the conventional, separate supply of electricity and heat. However, many CHP operators are wondering what they should do in the summer with the heat generated. The ideal answer here is the additional integration of an adsorption refrigeration system.

Fuel cells

Like gas-powered cogeneration plants, fuel cells generate electricity and heat, and with their relatively high cooling water temperature, they are particularly suitable for combined heat and power plants (CHP) and therefore also perfect for combining with adsorption chillers. This interaction is very beneficial in more ways than one: The generated electricity reduces electricity bills, and the cooling capacity is provided at the same time with almost no additional electricity needed.

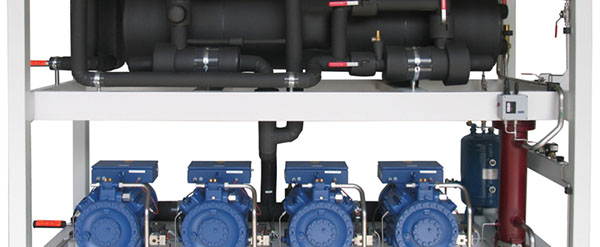

CO₂-Chillers

In order to be able to continue to operate their refrigeration systems without F-gases, which are increasingly being taken off the market, more and more supermarkets and other cooling system operators are turning to CO₂ systems. The waste heat from transcritical CO₂ chillers has exactly the right temperature level to drive adsorption cooling.

Compressed air

Almost all manufacturing companies use compressed air. At the same time, the need for cooling, both for production and for buildings, is constantly increasing, driving energy demand. Adsorption cooling offers an ideal approach for generating cold and reducing energy costs through heat recovery.

District Heat

local heat is usually generated together with electricity (combined heat and power). The efficiency of this process is much higher than with conventional power plants. This makes district heating an efficient and resource-saving option for energy supply. Their use becomes even smarter when district heating is used to drive an adsorption refrigeration system.

Process Waste Heat

Industry and trade need artificially generated refrigeration – and this demand is growing steadily. At the same time, electricity prices continue to rise. The increasingly stringent climate protection goals – and the associated regulations – also call for plant technology to be made energy-efficient and environmentally friendly. Many companies face challenges that can hardly be overcome with conventional solutions.

Solar Thermal

Cooling Applications

Building A/C

Our summers are getting hotter and hotter, and ensuring a comfortable indoor climate is just as important for office spaces as for production halls, hotels, or cinemas. Adsorption cooling systems from FAHRENHEIT generate the optimal temperature from waste heat. The heat can also be generated by cogeneration plants, from solar heat from the sun, or it can be directly obtained from production processes.

Warehouse Cooling

Reliable, uninterrupted cooling of sensitive products is an important quality aspect when it comes to manufacturing and storage, not just in the food industry. What’s more, employees working in warehouses also want a pleasant working temperature during the hotter months of the year.

Production Cooling

FAHRENHEITS’s adsorption cooling systems are robust, low-maintenance, and very reliable. This makes them particularly suitable for often demanding production environments. At the same time, they help you achieve your energy goals: Because they save up to 80% electricity compared to conventional cooling systems.

IT Cooling

Data centers consume an ever-increasing proportion of the electricity produced worldwide — reaching 4% already today. Cooling with conventional technologies contributes considerably to this high consumption. This is exactly where FAHRENHEIT cooling systems come in. Computer power is converted into waste heat.

Food Cooling

Bitte übersetzen – Die Adsorptionskältesysteme von FAHRENHEIT sind robust, wartungsarm und sehr zuverlässig. Daher eignen sie sich insbesondere auch für den Einsatz in der Lebensmittelbranche. Denn verlässliche, unterbrechungsfreie Kühlung ist eines der entscheidenden Qualitätskriterien bei der Herstellung und Lagerung von Lebensmitteln.

Vehicle Cooling

Bitte übersetzen – Die Fahrzeugbranche steht vor großen Herausforderungen: Weltweit steigende Verbrauchs- und Emissionsstandards treffen auf den technologischen Umbruch hin zur Elektromobilität. Gerade für die reale Verbrauchssenkung bei Verbrennungsmotoren ist Adsorptionskühlung ein idealer Hebel. Die Nutzung der Abwärme aus dem Abgasstrang und aus dem Kühlwasser ermöglicht die Klimatisierung des Innenraums von Pkws und Lkws – und das nicht nur während der Fahrt, sondern bei entsprechender Auslegung auch im Stand.

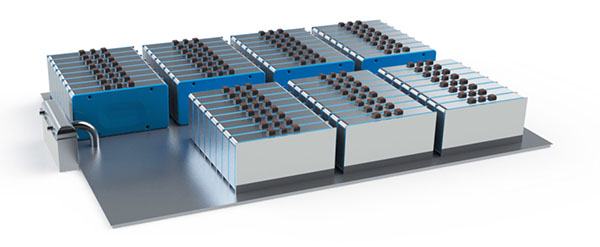

Battery Cooling

EV batteries are the core component of the mobility technology of the future. The increase in density and power of EV batteries goes along with higher heat generation, which has become significant during high-power charge or discharge events. At the same time, EV batteries last the longest when they are operated within a narrow temperature range of between 20 and 30°C.