EINFACH GENIAL – GENIAL EINFACH

ADSORPTIONSKÜHLUNG

Bei der Adsorptionskältetechnologie von FAHRENHEIT ist das Gas Wasserdampf – und die Oberfläche des Feststoffs ist mit Zeolith oder Silicagel (Kieselgel) beschichtet. Sie sind sehr porös und verfügen damit über eine außerordentlich große innere Oberfläche. So können sie sehr viele Wassermoleküle wie ein extrem leistungsfähiger Schwamm „aufsaugen“.

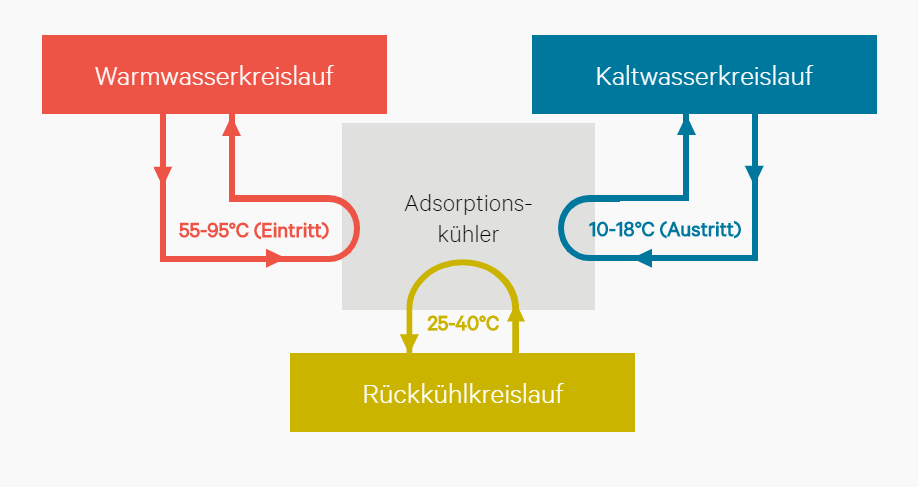

In den Kühlsystemen von FAHRENHEIT ist zudem ein Vakuum angelegt. Das Wasser verdampft hier also bereits bei deutlich geringeren Temperaturen, als dies unter normalen Druckverhältnissen möglich wäre. Durch die Anlagerung der Wassermoleküle am Adsorber verdampft das Wasser und kühlt sich ab. Über einen Wärmetauscher wird dadurch das Kühlmedium gekühlt.